Looking at homes built in the 40-50's. I have never seen narrow (1 1/2" wide) flooring. Can not tell if this is tongue and groove like 3" - 3 1/2" boards. Some homes have repaired these floors with boards nailed from top of board instead of side toenailed. Any of our resident experts have any experience with this flooring? Looking at calculating cost to correct these issues after purchase. Thanks in advance and have a happy safe new year.

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Oak Flooring Question

- Thread starter ORCUS DEMENS

- Start date

Renovated a lake cabin several years ago that was built in 1952 and discovered maple hardwood flooring when the carpet was removed. Similar dimensions as noted above. It was tongue and groove. Rented a sander and refinished the hardwood. We did have to repair a couple of boards. I used a pneumatic brad nailer from top. Used colored filler and sealed with super-poly. Turned out great considering I had no idea what I was doing.

Folks put same flooring in upstairs of home back in 1950 something. Was 3/4 inch thick and toe nail in with finishing nails. Put on top of i assume oak boards from back in earlier 1900. Had to drill holes first before putting nails in. So good to sand if that works but in the old home, the floor is as good as the day it was put in except they put carpeting over the oak for whatever reason in the hall way.

My accident with a 22 rifle going off and just missing my foot did not penetrate the flooring into the ceiling down stairs. As far as i know, parents never found out about that one. db

My accident with a 22 rifle going off and just missing my foot did not penetrate the flooring into the ceiling down stairs. As far as i know, parents never found out about that one. db

Retired Educator

★★★★★ Legendary Member

^^^^ You're lucky with the floor. My 12 ga. going off towards the ceiling was pretty hard to hide. Have no idea why I decided to pull the trigger to check if the gun was loaded. Only explanation is it was a dumb thought.

Thanks gentleman, Some of the homes I looked at had repaired flooring that would not be up to my usual standards. I am curious as to why the floors were installed in this fashion, more labor/time to install, more fasteners per square foot, so overall higher cost per square foot. Wirehair, maple flooring like that is common for bowling alleys. I have heard of that being reclaimed when lanes are relayed after years of use. Must be sweet looking and hard as rock.

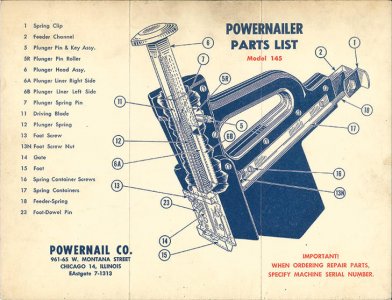

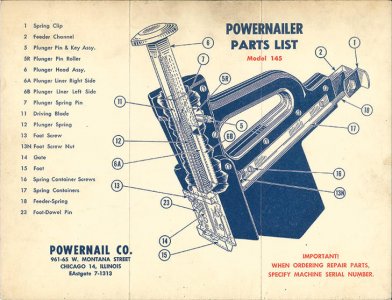

Tongue and groove flooring has been around since the early 1800's some houses of post industrial age t&g wood was done by hand using mortison and tendon type interlocking. Since t&g flooring was either fastend down using a hand drive or a cleat style fastener The reason for the 1.5 inch wide by 3/8,5/8, or commercial 3/4" thicknesses because it was easier to get a tight fit and wood was not always the straightest making it easier to get the bows out when nailing down, The t&g are milled in such a way as the wood needs to forced together to ensure a tight fit. Hence the reason why today we us an air stapler that needs to be hit with a mallet to ensure a tight fit.

If you have a board that has been faced nailed that is not around the parameter of the room, it is most likely a board that has become loose over the years because older houses in climates that have seasonal weather expand and contract causing the nails to lossen up over time. The other could be that a board was replaced because of damage for some reason or another, when the board was replaced the new board had the tongue removed and the bottom wood strip removed on the groove side so the board could be installed and the face would be nailed down.

Usually after the hardwood floors were fixed of squeaking and damage caused by rodents, water stains, or heavy objects the floors wouks be sanded down to bare wood nail holes wood be filled as well as cracks or knots that have dried out. Then you would sand the floor atleast 2 more times depending on the hardness of the wood. A maple, walnut, Mahogany, Brazilian cherry (jatoba wood) some of your harder woods that may need to be sanded in steps using finer grits to take out the scratches ( swirls caused by the sander) Oak is one of the woods that usually only needs to be sanded a few times to get the floor ready so it can be sealed with some sort of protective coating.

- - - Updated - - -

If you have a board that has been faced nailed that is not around the parameter of the room, it is most likely a board that has become loose over the years because older houses in climates that have seasonal weather expand and contract causing the nails to lossen up over time. The other could be that a board was replaced because of damage for some reason or another, when the board was replaced the new board had the tongue removed and the bottom wood strip removed on the groove side so the board could be installed and the face would be nailed down.

Usually after the hardwood floors were fixed of squeaking and damage caused by rodents, water stains, or heavy objects the floors wouks be sanded down to bare wood nail holes wood be filled as well as cracks or knots that have dried out. Then you would sand the floor atleast 2 more times depending on the hardness of the wood. A maple, walnut, Mahogany, Brazilian cherry (jatoba wood) some of your harder woods that may need to be sanded in steps using finer grits to take out the scratches ( swirls caused by the sander) Oak is one of the woods that usually only needs to be sanded a few times to get the floor ready so it can be sealed with some sort of protective coating.

- - - Updated - - -

Last edited:

Similar threads

Recent Posts

-

Northern Lights

- Latest: sdwxman

-

Oahe report Mobridge

- Latest: sdwxman

-

Representative Dockter

- Latest: Lycanthrope

-

Vanguard 257 Weatherby Magnum

- Latest: SDMF

-

Portable Fish House Storage

- Latest: johnr

-

Haze

- Latest: johnr

-

FOR SALE - 14 FOOT LUND BOAT

- Latest: Retired-Guy

-

RR Red River 5-8-24

- Latest: luvcatchingbass

-

Wicked Waters Taxidermy

- Latest: NodakBob

-

Velocitor V Stinger

- Latest: PrairieGhost

-

Kristi Noem Dog Killer

- Latest: guywhofishes

-

New Hazards in the Tailrace

- Latest: MSA

-

Transporting Fish Question ??

- Latest: Rowdie

-

Sak Sak - New Town Area 5/4

- Latest: 701FishSlayer

-

No Mow May

- Latest: johnr

-

Minn kota I-pilot link swap

- Latest: 701FishSlayer

-

Any Birders here?

- Latest: Davey Crockett

-

Tailrace trout

- Latest: svnmag

-

Sale Marlin 30TK

- Latest: svnmag

-

What are you listening to these days?

- Latest: svnmag

Friends of NDA

Top Posters of the Month

-

This month: 61

-

- Posts

- 1,047

-

- Likes

- 938

-