I'd pay brokeback $200 to just manage the damn project for me

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Need to build an approach, suggestions?

- Thread starter Lycanthrope

- Start date

Talk with local farmers/ranchers or maybe the landfill. Another good source is dirt contractors if they don't have it they usually know where to get it. Heck maybe even talk with the township supervisor's they might know someone local.I hadnt thought about fires... Good point! Where would one source good fill clay material?

Do you have enough acres where you can dig a water hole for the wildlife and use that to build your approach?

- - - Updated - - -

Heck when i was back in ND i would have been more than happy to help you get it lined up and not charged you one red cent. Are you doing this in or around Bismarck or a different location in ND?I'd pay brokeback $200 to just manage the damn project for me

- - - Updated - - -

Township rules and regs first then go from there.

Absolutely start there as you don't want to do it and then find out you have to take it out as it is in the wrong spot or not done to their specs!!!

Last edited:

bbj, I meant lycan should hire you

things are so damn easy once you’ve done them a bunch like you have

near freaking impossible with no experience- drives me bonkers

- - - Updated - - -

the water hole is a smashing idea

things are so damn easy once you’ve done them a bunch like you have

near freaking impossible with no experience- drives me bonkers

- - - Updated - - -

the water hole is a smashing idea

Had some that insisted that we use their rock piles to build up the base of their approach and then top it off with clay. Worked good and built up fast but like i told them in 5-10 years you might have rocks pushing up in your approach. When it turned wet the rocks did work their way up as the frost pushed them up.

If you have a big hill or hills on your land you can push the black dirt off and take the clay from the hill and push the black dirt back on. Lots of options. If you know of a guy local with a backhoe or payloader that is perfect. Just make sure they compact it good by working it back and forth. A good backhoe operator knows this.

If you have a big hill or hills on your land you can push the black dirt off and take the clay from the hill and push the black dirt back on. Lots of options. If you know of a guy local with a backhoe or payloader that is perfect. Just make sure they compact it good by working it back and forth. A good backhoe operator knows this.

Last edited:

What Brokeback said. When putting the top on use crushed rock or concrete rubble, as it will not move or push around like gravel or round rock, as it kind of locks together.

roosterfish

★★★ Legendary Member

- Joined

- Dec 25, 2016

- Posts

- 412

- Likes

- 5

- Points

- 128

talk to county for sure. If this is in a development keep in mind in most cases you are only allowed one per lot, believe me i went through this debacle already. You can petition for a second but it has to go through county commisisoners mtg. Wider the better,metal for sure and have a load of regrind delivered for the top soil.

Here's a link to the Burleigh counties website for approaches. There is also a link in there for the construction standards. http://www.burleighco.com/departments/hwy/approaches/

It seems most people are in different camps on the material of the culvert. Anyone care to elaborate more into why they prefer galvanized, double wall poly, or concrete?

Double wall HDPE with a smooth interior would offer the best flow, longest material life, looks to be the least expensive of the three and likely easiest to handle. Downsides would be load it can carry and fire like mentioned, but if neither of those are major concerns due to location, use, and backfill depth would it not be the best choice?

Double wall HDPE with a smooth interior would offer the best flow, longest material life, looks to be the least expensive of the three and likely easiest to handle. Downsides would be load it can carry and fire like mentioned, but if neither of those are major concerns due to location, use, and backfill depth would it not be the best choice?

A friend built a house up a mile from his dads ranch off of a county road, was going to make it wide for equip, truck loads of hay etc, the county would not permit it for much width ! ( don't know how wide he was asking )

- Joined

- Nov 2, 2015

- Posts

- 743

- Likes

- 30

- Points

- 173

Absolutly nothing wrong with an HDPE culvert. This coming from a guy that does this for a living. Kick it in the ditch and fill it in. Make sure there are no sags in the middle otherwise issues with ice trapping water upstream in the spring.

Was out fixing a road built out if clay yesterday sure it gets hard when dry but get it wet you are sol. There is a reason expansive materials are not used or recommend for a base material on engineered projects.

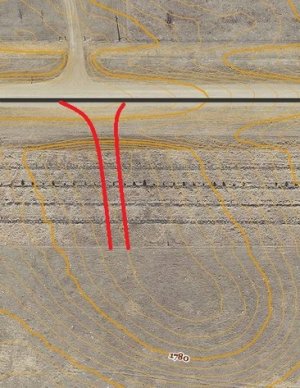

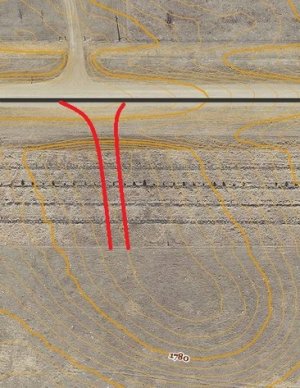

Got a quote from a guy with some heavy equipment yesterday. To build the approach, at the crest of a slight hill, he wants $1800. He said he can use a dozer to push off the topsoil and use subsoil from the hill to build the approach. Its a fairly deep and wide ditch so he estimates we would need a 45ft culvert (not included in cost) and approximate 35 yards of gravel to put 6" on top (also not included in cost). For those with experience, is this reasonable? He figured he could do the whole project in a day... Here is a picture of the actual property/ditch...

That’s not to bad. Figured a 10 hour day that’s 180 for dozer and labor

So roughly saying he is $180 an hour and figures 10 hours or $250 an hour and 7.2 hours plus you furnish all materials. While not seeing the property he should easily get done in a day. Probably ok price nowadays and he is probably busy so if you want it done, you pay the price.

Personally i wouldn't use gravel for the top i would use crushed asphalt. Like i said before pour the water to it when done and pack it down and it sets up like concrete. The gravel rocks you will be carrying out in your tires and if you move snow and push it, it will move with the snow unless you leave a snow base. I would think Bismarck has lots of crushed or ground up asphalt. But the choice is yours.

Good luck Lycan and let us know how it goes. :;:thumbsup

Personally i wouldn't use gravel for the top i would use crushed asphalt. Like i said before pour the water to it when done and pack it down and it sets up like concrete. The gravel rocks you will be carrying out in your tires and if you move snow and push it, it will move with the snow unless you leave a snow base. I would think Bismarck has lots of crushed or ground up asphalt. But the choice is yours.

Good luck Lycan and let us know how it goes. :;:thumbsup

I mentioned using other material to him and he said cost is 2x as much and its not as easy to 'renovate' when it needs work. He actually suggested using more like 'rock' than gravel, he said something like 1.5" up to 3" material and then if it needs work, he said all you need to do is get a scarifier (4-5 shallow claws) attached to a box blade or skidder and it will lift the rock back to the surface and allow the dirt to work its way back down. Says hes done a lot of approaches and thats the easiest to maintain... Sound legit?

Last edited:

Good design to gravel a path into/between the tree row.

I'd consider having a "gravel staging pad" built for you to park/store/work on things while you develop the property (off sharply to one side on the back of the tree rows so what is stored/left there is hidden by tree row in coming years - on that hilltop looks ideal). Working on or parking things on anything but nice gravel is BS when it's wet.

I'd consider having a "gravel staging pad" built for you to park/store/work on things while you develop the property (off sharply to one side on the back of the tree rows so what is stored/left there is hidden by tree row in coming years - on that hilltop looks ideal). Working on or parking things on anything but nice gravel is BS when it's wet.

It was like 10 years ago that i quit doing dirt work so prices have really gone up since then. I used to get 10-12 yards of crushed asphalt for less than $3.00 a yard. If the approach is built correctly you should never have to renovate it, but every contractor is different. I can understand him using big rock if he can pack it in. I used 3/4'' crushed rock when i couldn't get the crushed asphalt, and i packed it in while the clay was still wet and that worked good too.I mentioned using other material to him and he said cost is 2x as much and its not as easy to 'renovate' when it needs work. He actually suggested using more like 'rock' than gravel, he said something like 1.5" up to 3" material and then if it needs work, he said all you need to do is get a scarifier (4-5 shallow claws) attached to a box blade or skidder and it will lift the rock back to the surface and allow the dirt to work its way back down. Says hes done a lot of approaches and thats the easiest to maintain... Sound legit?

Once i used the crushed asphalt that was my preferred topping for certain projects. In spongey yards i would use 1 1/2''- 3'' rock to pack it down good and firm it up. That fixed the spongey spots but sometimes you had to do it for 1-3 years in a row to get it totally firmed up. By spongey i mean the frost boil spots that some yards get in the spring. Others might have different views on what works for them.

Similar threads

- Replies

- 29

- Views

- 6K

Recent Posts

-

Bismarck roads and driving

- Latest: jdfisherman

-

NFL News (Vikings)

- Latest: Kurtr

-

Coffee and sweet beaver

- Latest: Maddog

-

Riddle Me This.....

- Latest: Maddog

-

Answer me this

- Latest: LBrandt

-

I Love This Bar (NDA)

- Latest: NG3067

-

Presidents who added the most

- Latest: grumster

-

More CWD NE ND

- Latest: grumster

-

Quiet Pellet Gun

- Latest: Captain Ahab

-

Drotto adjustment?

- Latest: Fester

-

Check your bags boys

- Latest: svnmag

-

Tractors

- Latest: Davey Crockett

-

Spring snows 24

- Latest: 870XPRS

-

Tract Optics

- Latest: rodcontrol

-

Any Birders here?

- Latest: svnmag

-

Prairie ghost

- Latest: johnr

-

A good movie

- Latest: gillraker

-

Skinwalker Ranch

- Latest: svnmag

Friends of NDA

Top Posters of the Month

-

This month: 190

-

- Posts

- 968

-

- Likes

- 869

-

-

This month: 114

-

- Posts

- 2,012

-

- Likes

- 837

-

-

This month: 95

-

- Posts

- 1,409

-

- Likes

- 976

-

-

This month: 88

-

- Posts

- 521

-

- Likes

- 205

-