So after one attempt putting a new inline water filter I don't feel like doing it three times so looking for info on the best pipe dope/joint compound when joining 3/4" copper threaded fittings into the plastic housing for the water filter housing. I used my trusty "Leak Lock" and got a leak so desoldering and starting over, just wanted to know what other guys use for male copper threads to plastic female threads. Thanks in advance!

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Any plumbers on here?

- Thread starter USMCDI

- Start date

Plumber's tape? White stuff in a small spool. https://www.homedepot.com/p/1-2-in-x-260-in-PTFE-Tape-0178502/202280370

Plumber's tape? White stuff in a small spool. https://www.homedepot.com/p/1-2-in-x-260-in-PTFE-Tape-0178502/202280370

Thanks but I don't think teflon tape is gonna cut it, if I didn't have to solder copper pipes after the threaded joint goes into the housing I'd wrap the shit out of the threads but it's a total pain in the ass because I can't get all of the water out of the line so I have to cut it each time it leaks and make a new pipe. There's enough of an angle that I can't blow it out from the housing so I just wanted to see what other guys have used. If there's a tablespoon of water in the line you'll never get the pipe hot enough to desolder the joint.

The plumbers I've worked with shove a piece of bread (no crust) up the pipe to hold the water back and then after soldering they turn the water on and blow the bread out before finishing.

ps: You wad the bread all up in a ball and force it up the pipe. Then wipe the inside with a dry cloth on a rod/screw driver and make the soldered connection.

ps: You wad the bread all up in a ball and force it up the pipe. Then wipe the inside with a dry cloth on a rod/screw driver and make the soldered connection.

Last edited by a moderator:

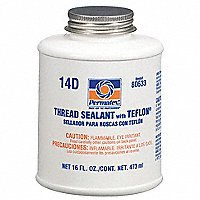

Yup, that's my next move, gonna cut that pipe a fraction shorter so there's enough of an angle for it to drain, don't want to do it three times so hopefully that Permatex works. I wish "The Right Stufff" made pipe dope, I don't even use header gaskets anymore just a bead of "The Right Stuff" and never had a header leak but that shit is brutal to remove.

if you soldered that male pipe joint that was screwed into the plastic while it was screwed into the plastic your probably screwed. you need to do up the pipe joints off the plastic as far as you can. Then solder the last fitting to that vertical run of pipe. I would have bought a male pipe/compression fitting to put in there. That way you can make up all the pipe before you have to install the filter housing. The pipe them just slides into that compression fitting not requiring a solder joint.

I was just thinking of what I have at our cabin on Metigoshe. We use lake water in the cabin for washing etc. and haul drinking/cooking water. I have a canister filter to take the algae out of the water. I have a ball valve on each side of the canister to turn the water off from the pump and from the cabin when I change the filter. Do you need something like that?

if you soldered that male pipe joint that was screwed into the plastic while it was screwed into the plastic your probably screwed. you need to do up the pipe joints off the plastic as far as you can. Then solder the last fitting to that vertical run of pipe. I would have bought a male pipe/compression fitting to put in there. That way you can make up all the pipe before you have to install the filter housing. The pipe them just slides into that compression fitting not requiring a solder joint.

True, but I soldered everything close to the plastic while it was not connected note the sharpie marks for alignment. I soldered the union last, closest to the wall with a wet rag over the pipe going to the plastic trying not to warp the plastic. The old one didn't leak until the relief valve took a shit and I did it the same way, just thinking my pipe dope was old or something and there has to be some better stuff out there, been 20 years since I did it the first time.

- - - Updated - - -

.I was just thinking of what I have at our cabin on Metigoshe. We use lake water in the cabin for washing etc. and haul drinking/cooking water. I have a canister filter to take the algae out of the water. I have a ball valve on each side of the canister to turn the water off from the pump and from the cabin when I change the filter. Do you need something like that?

I do have a valve for the inlet but this filter goes straight to an extra faucet on our sink that we have that doesn't get softened water. Don't ask me why, someone thinks it's bad to drink softened water, "You mean we're drinking all of that salt?" WTF right?

eliminator

Honored Member

Just a question I guess more than anything but don't they make a shark connection that would work for this. I know you can use them on copper and plastic and to me that would be easier than trying to solder I use these things a lot at home and they work awesome but maybe can't be used in this case

I do have a valve for the inlet but this filter goes straight to an extra faucet on our sink that we have that doesn't get softened water. Don't ask me why, someone thinks it's bad to drink softened water, "You mean we're drinking all of that salt?" WTF right?

When I remodeled/added a second story on our house in '93 we softened all the water in our house except for the 2 kitchen colds at the sinks and the ice maker at the refer. That was just to improve the taste of drinking and cooking water. The added benefit is that now when we go to ND for the summer I turn the softener off, close the 3 angle stops for the 2 sinks and refer and there is no water on in the house. With 1200 sf of hardwood floor I don't need a 5 month water leak.

ps: I think that you will find that using unsoftened water for drinking, cooking and coffee will improve the taste of everything.

should have put a union in between the wall elbow and the filter that way you could work on both sides before hooking them together

Oh there's one going on this time, I'm done playing with water in the lines.

cut it back 3 inches and use a shark bite coupler

They work alright but soldered copper pipe is hard to beat and it still doesn't fix my problem, the filter head has female threads on each side.

- - - Updated - - -

Teflon(ptfe) tape and Rectorseal pipe dope...DONE. Father was a plumber for 30+ years and used it without leaks exclusively..

Which one? There's the soft seal black stuff that never really hardens or the Tru Blue?

Similar threads

Recent Posts

-

Representative Dockter

- Latest: Wall-eyes

-

Transporting Fish Question ??

- Latest: 701FishSlayer

-

Sak Sak - New Town Area 5/4

- Latest: 701FishSlayer

-

Minn kota I-pilot link swap

- Latest: 701FishSlayer

-

Oahe report Mobridge

- Latest: sdwxman

-

Wicked Waters Taxidermy

- Latest: bluedevil

-

Kristi Noem Dog Killer

- Latest: johnr

-

Velocitor V Stinger

- Latest: Lycanthrope

-

Northern Lights

- Latest: SDMF

-

Any Birders here?

- Latest: Davey Crockett

-

Tailrace trout

- Latest: svnmag

-

Sale Marlin 30TK

- Latest: svnmag

-

What are you listening to these days?

- Latest: svnmag

-

This is what its all about

- Latest: wslayer

-

Merino Undies

- Latest: wslayer

-

Buying gold and silver.

- Latest: grumster

-

SOLD Elec Power Washer

- Latest: Zogman

-

What boat ramp open in Bismark

- Latest: Sluggo

-

No Mow May

- Latest: lunkerslayer

Friends of NDA

Top Posters of the Month

-

This month: 61

-

- Posts

- 1,047

-

- Likes

- 938

-